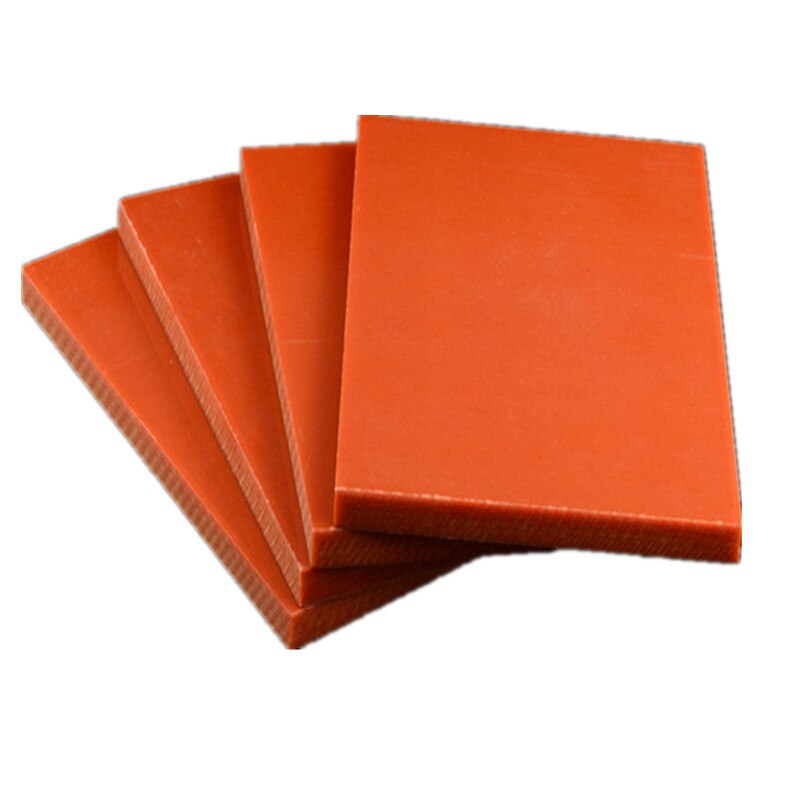

Fabric Bakelite Sheets & Rods

Description :

Fabric Bakelite is a phenolic rigid laminate reinforced by a woven cloth, for use in mechanical and structural applications. Bakelite sheet is a hard, dense material made by applying heat and pressure to layers of paper or glass cloth impregnated with phenolic resin. These layers of laminations are usually of cellulose paper, cotton fabrics, synthetic yarn fabrics, glass fabrics or unwoven fabrics. When heat and pressure are applied to the layers, a chemical reaction (polymerization) transforms the layers into a high-pressure thermosetting industrial laminated plastic. It offers excellent mechanical and wear resistance. It is suitable for gears and similar applications requiring high impact strength. There are several types of fabric Bakelite eg. F1, F2, F3.Product Details :

Thickness 1 mm to 100 mm in 4 ft. x 4 ft. and 8 ft. x 4 ft. of sheet size.

Sheets can be cut according to given size as per order

Diameter 6 mm to 150 mm in 2 ft. and 1 ft. of length

.jpg)